NEOPHIL®

The new generation of fluoropolymer hollow fiber membranes

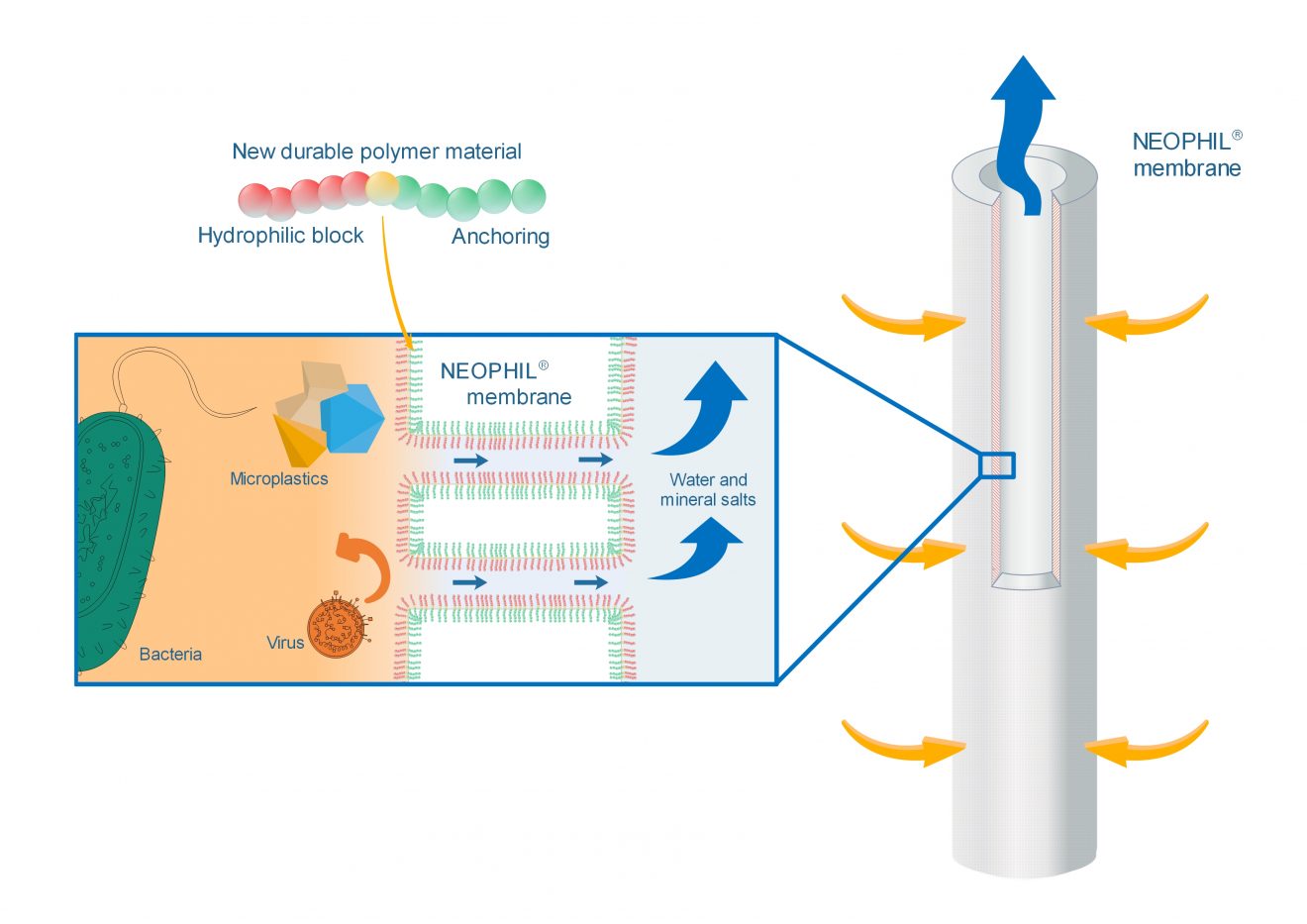

Polymem, in partnership with Arkema, has developed the new generation of ultrafiltration membranes called NEOPHIL®, which is made from a uniquely modified PVDF.

The modification is based on a proprietary block copolymer, which is solidly anchored within the Arkema Kynar® PVDF matrix and provides durable hydroydrophilicity to the inner and outer membrane surfaces.

In addition, this modification’s strong resistance to oxidation ensures that it will persist and be effective throughout the entire lifetime of the membrane.

The NEOPHIL® material is offering unique benefits

The polymeric materials making up the NEOPHIL® membrane consist of Kynar® PVDF and a copolymer anchored within the structure:

1/ Kynar® PVDF gives the microporous membrane both its chemical resistance to oxidants and its superior mechanical strength

2/The copolymer gives the membrane its permanent hydrophilic property and a stable porous structure

Unique association of benefits

-

-

-

-

- Resistance to Oxidants (chlorine, ozone…)

- High and permanent Permeability

- Excellent Mechanical Resistance (Tensile force and Elongation at break)

- Permanent Structure and surface Rejection

- BPA free, BPS free fiber membranes

-

-

-

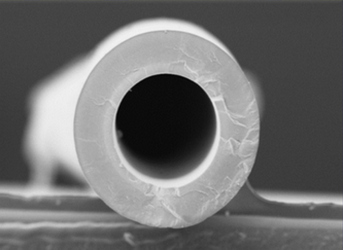

S2F Polymem standard NEOPHIL® fiber

NEOPHIL® fiber with its hydrophilizing additive incorporated into the membrane material, is not subject to performance losses. Polymem’s hollow fiber manufacturing process with NEOPHIL® generates very small pore sizes for retaining viruses, which is otherwise difficult to achieve with conventional PVDF.

-

-

-

-

- Pore diameter : 0.015 µm true UF membrane with a very narrow pore size distribution profile

- High mechanical resistance

- Resistance to chlorine (whatever the pH)

- High hydrophilicity when new AND after ageing

- The permanence of hydrophilicity of NEOPHIL® ensures the control of energy and chemicals consumption over time.

- Resistance to biodegradation

-

-

-

The stability of the porous structure ensures the durability of excellent treatment performance and thus of virus rejection rate:

Virus removal > 4 log on new fiber

AND

Virus removal > à 4 log on aged fibers (exposed to 200 000 ppm.h chlorine)

A range of NEOPHIL® hollow fibers

Polymem designs and manufactures a range of NEOPHIL® hollow fibers that are designed for various applications: Ultrafiltration (standard S2F), Microfiltration (MFF) for disposable cartridges, supported NEOPHIL® for submerged MBR modules …

Ask us about your NEOPHIL® membrane application !